Quality Makes Us Global

The Global Air Commitment to Quality

Aerospace Quality Certification: AS9100

It comes as no surprise that the aerospace industry has unique quality management demands. Any company that designs, develops, makes, or supplies products and services for aviation, space, or related defense and military applications, needs to achieve this certification for long-term industry success. These standards have evolved over the past couple decades to put greater emphasis on risk management and specific measures to verify the effectiveness of quality systems related to requirements conformance and on-time delivery performance. Here’s a link to the PDF of Global Air’s current AS9100 certification:

Rolls Royce Certificate of Approval

ISO 9001: General Excellence in Quality Management

These fundamentals of QMS include the seven principles of quality management that undergird the entire ISO 9000 family of standards. Meeting the specific requirements of ISO 9001 is confirmed by a third-party certification with an eye on demonstrating a commitment to continual improvement. Research has shown that implementation of these standards results in better operational and financial performance. Here’s a link to the PDF of Global Air’s current ISO 9001 certification:

CMM: Coordinate Measurement Machine

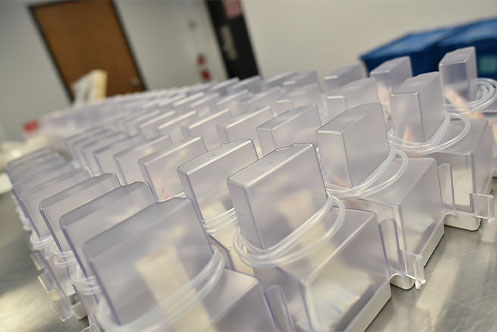

Machine Vision (Optical Inspection System)

Optical Comparator

Achieving and maintaining the three key quality certifications mentioned above is an accomplishment in which we take pride because it is an outward demonstration of our deep commitment to quality in every project for every customer client. Other companies may talk a good game about quality, but at Global Air we live and breathe it day in and day out. Learn more by getting in touch with us through the Contact Us page of our website.