Global Air Product Information

Quality Makes Us Global

Global Air Product Information

Regardless of the specific application, aviation requires higher attention to quality than most industries. After all, taking flight is no small feat, and the physical forces at play in a turbine engine are extreme. The metal components we make for turbine engines must be able to withstand very high temperatures and incredible stresses experienced during operation. Global Air take pride in having achieved aerospace quality certification AS9100 as well as a coveted and even more stringent Rolls Royce Certificate of Approval for the turbine engine components we make.

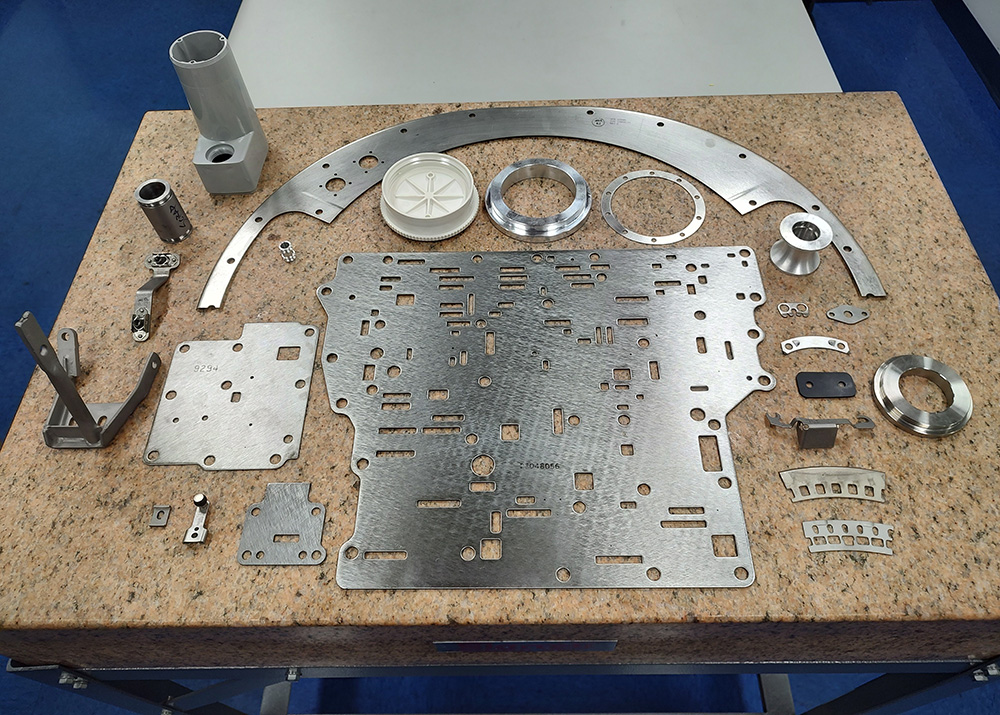

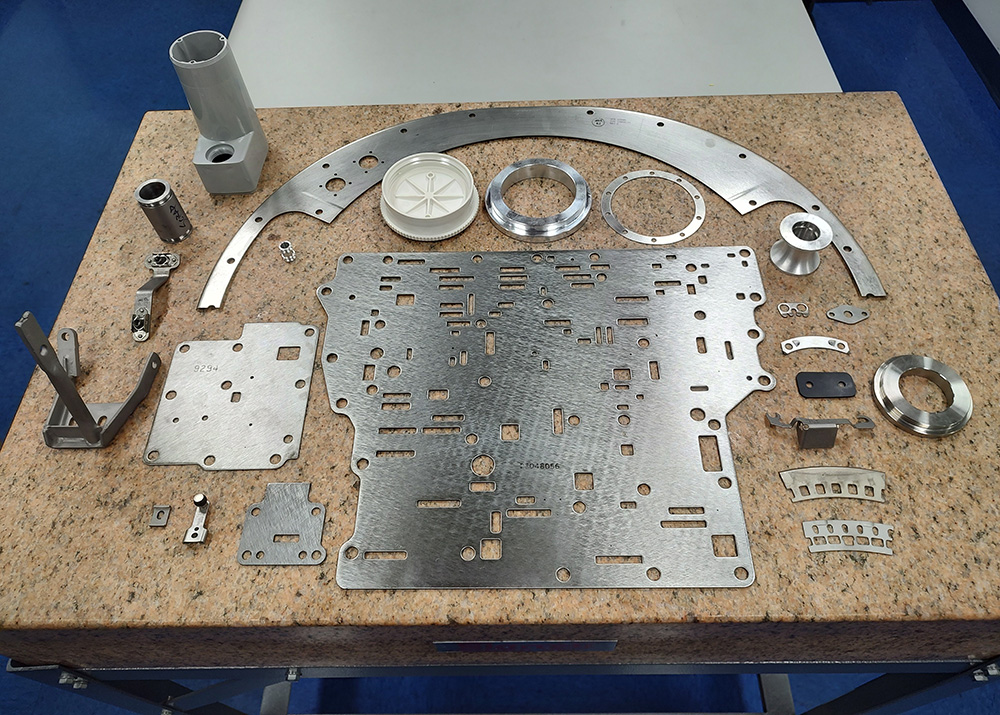

What all these different kinds of vehicles that help get work done across America and beyond have in common is a transmission. Inside all those different transmissions are metal plates that separate various transmission components. These metal separator plates must have dozens of different holes and slots that allow for the flow of oil and provide passage for wiring.

The vehicles into which these transmissions are installed are called upon for heavy-duty usage, which means our metal separator plates must be strong (up to an inch thick) enough to withstand high stress along with highly precise placement of the holes and slots. Global Air has perfected the process of machining these transmission parts with precision, quality, and durability needed to keep the nation’s hard-working vehicles moving. We also have the capacity make a huge variety of metal brackets used in a wide variety of applications in those same vehicles.

High-Performance Racing Components

Given our location in Indianapolis, it should come as no surprise that Global Air has proudly served the motorsports industry. When racecars are hurtling around a racetrack such as the Indianapolis Motor Speedway, it is critical they minimize the space between them and the asphalt. In fact, it may seem like there is nothing separating the car from the track, but there is. Global Air makes undercarriage plates for racecars. Quality in this environment calls for very tight tolerances while achieving durability and strength while keeping the component as lightweight as possible. It’s a high-performance context requiring the highest precision possible, and we deliver. We also have the capacity to make all manner of metal brackets used throughout racecar vehicles.

When your company needs a metal part made right the first time, Global Air has the machining expertise and equipment to get the job done on-time while maintaining the highest industry standards in the quality of our products. We invite you to learn more by getting in touch with us through the Contact Us page of our website.