Capabilities

Superior Capabilities for Precision Components and Parts

While we can achieve high precision and tight tolerances, along with good finishes on parts and components using conventional machining methods, even greater precision and finish control is possible with our non-conventional machining methods outlined below.

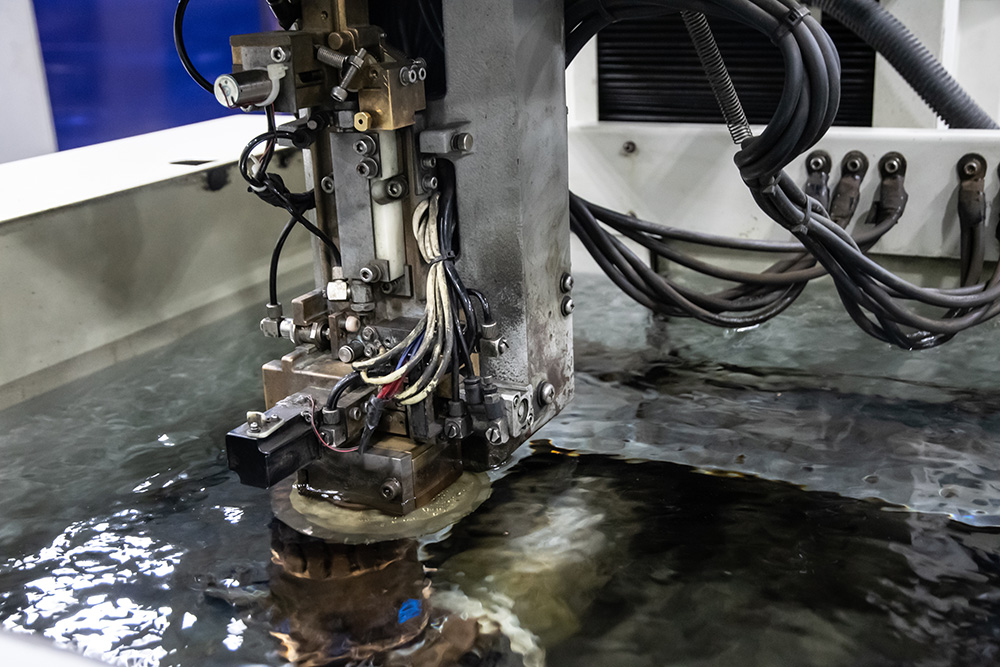

CNC Water Jet Machining

CNC Laser Cutting

Wire EDM

When two parts need to be joined together to make a complete component, Global Air has both brazing and welding capabilities as outlined below:

Brazing

MIG and TIG Welding

If parts need to be marked with logos, serial numbers, part numbers, bar codes, or other information, we use three different techniques for marking parts. Our dot peening machine uses a vibrating punch to produce a series of evenly spaced tiny indentations (dots) on the surface of a part. This is a fully automated, programmable, high-speed process that can produce various fonts, font sizes, and simple images (but not high resolution). For especially hard surfaces that don’t take dot peening well, chemical etching is a cost-effective alternative that also doesn’t alter the part’s surface the way dot peening does. Finally, electrochemical etching is another alternative that can produce clearer images when needed.

Our tooling department is top-notch in expertise and state-of-the-art equipment to make a variety of tools such as dies, gauges, and fixtures (such as drilling fixtures) to be used in machining metal parts and components. Machining methods used in this department run the gamut of both conventional and non-conventional in producing the right tools for each client project.

Global Air also offers full-service plastic injection molding services and tooling for precision plastic parts that can be used in a wide variety of aerospace and automotive applications.